Table of Contents

The CNR-LHD-80D Underground Mining LHD Loader is an innovative piece of machinery designed to revolutionize underground mining operations. With its cutting-edge features, this underground loader is the ultimate solution for handling materials in tight, underground environments. If you’re in the mining industry, understanding the capabilities of the CNR-LHD-80D Underground Mining LHD Loader will show you why this machine is a game-changer.

1. High-End Configuration

The CNR-LHD-80D Underground Mining LHD Loader is equipped with premium components sourced from globally recognized brands. These include the Euro III emission Volvo engine, a Dana torque converter, a gearbox, a Rexroth pump, and Parker valve groups. These high-quality parts ensure that the CNR-LHD-80D Underground Mining LHD Loader delivers unmatched stability and performance under the harshest conditions.

2. Advanced Hydraulic System

The hydraulic system of the CNR-LHD-80D Underground Mining LHD Loader is designed for efficiency and reliability. With a load feedback variable system and hydraulic confluence, this loader optimizes energy use, reducing failure rates and extending the lifespan of hydraulic components. This translates to a machine that can operate smoothly and efficiently, minimizing downtime.

3. Simple and Intuitive Operation

Operating the CNR-LHD-80D Underground Mining LHD Loader is a breeze, thanks to its electro-hydraulic proportional pilot control system. The integration of walking, steering, and working functions into two electronic control handles simplifies the operation, making it user-friendly even for those new to the machine. This ease of operation significantly enhances driver comfort and efficiency.

4. Unmatched Driving Comfort

The CNR-LHD-80D Underground Mining LHD Loader features an ergonomically designed enclosed cab, equipped with air conditioning and a fresh air system. The spacious cab and double shock absorption design (cab and air suspension seat) ensure that operators experience maximum comfort, even during long hours underground.

5. Safety and Reliability

Safety is paramount in mining operations, and the CNR-LHD-80D Underground Mining LHD Loader doesn’t disappoint. The cab meets FOPS and ROPS standards, ensuring protection in case of rollovers or falling objects. The loader’s braking system, which includes a spring brake and hydraulic release wet spring brake, enhances traction and reduces tire wear, further improving safety and reliability.

6. Distinctive Appearance

The CNR-LHD-80D Underground Mining LHD Loader boasts a modern and stylish design that reflects its advanced engineering. This visually appealing design not only looks great but also incorporates functional elements that contribute to the machine’s high performance and recognition on-site.

7. Ease of Maintenance

Maintenance is simplified with the CNR-LHD-80D Underground Mining LHD Loader. A centralized lubrication system and strategically placed filter elements make it easy to perform one-stop maintenance, reducing the time and effort required to keep the machine running at its best.

8. Personalized Customization Options

Every mining operation is unique, and the CNR-LHD-80D Underground Mining LHD Loader offers a range of customizable options to meet specific needs. Whether it’s remote control, automatic weighing, tire pressure monitoring, or boom suspension, this loader can be tailored to handle various working conditions and bucket capacities.

9. Powerful Technical Specifications

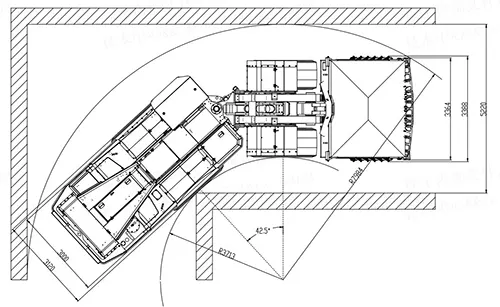

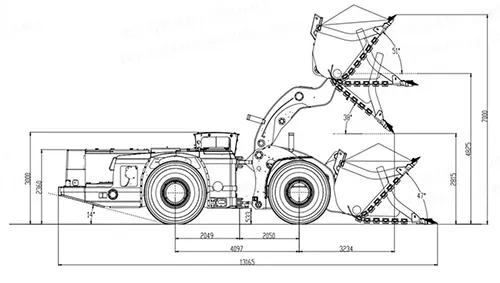

The CNR-LHD-80D Underground Mining LHD Loader is not just about looks; it’s about performance. With a rated load of 21 tons, a maximum shoveling force of 220 kN, and a travel speed of up to 25.9 km/h, this loader is built to handle the toughest underground jobs. The Volvo engine, Dana transmission, and Kessler axles further enhance its performance, ensuring that the loader operates with power and precision.

10. State-of-the-Art Security Features

Security is a top priority, and the CNR-LHD-80D Underground Mining LHD Loader is equipped with multiple safety features, including a centralized fire extinguishing system, exhaust pipe insulation, and radiator fan shields. These features, combined with advanced control systems and real-time monitoring, ensure that the loader operates safely in even the most challenging environments.