Table of Contents

CNR LHD loaders are engineered to excel in the toughest underground environments, delivering power, reliability, and efficiency in every operation. These machines are vital in mining operations, where navigating narrow tunnels and handling heavy loads are daily challenges. In this blog, we’ll dive into five key features that make the CNR LHD loader an indispensable tool in the world of underground mining.

1. Turbocharged Power System

At the heart of the CNR LHD loader is its robust power system, designed to tackle the most demanding underground conditions. The loader is equipped with a turbocharged engine that offers substantial torque reserves and delivers powerful, consistent performance. This engine is not just powerful; it’s also remarkably resilient, designed to withstand the rigors of high temperatures, humidity, and other harsh underground conditions.

The turbocharged engine ensures adequate air intake even at high altitudes, leading to efficient combustion, reduced emissions, and minimal tunnel pollution. This is particularly crucial in underground mining, where air quality can be a significant concern. The engine’s low failure rate and ease of maintenance further enhance its reliability, making it a favorite among operators who need equipment that can perform consistently in tough environments.

2. Advanced Transmission System

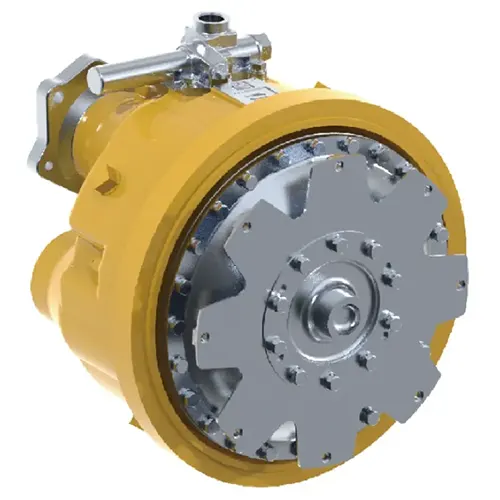

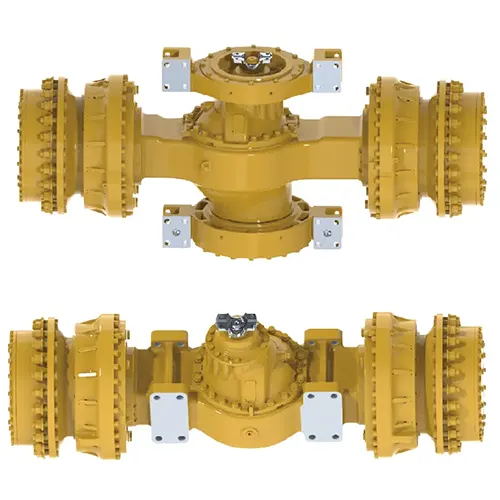

The CNR LHD loader is equipped with a high-quality transmission system that ensures seamless and efficient power delivery. The loader features a high quality torque converter and a robust gearbox, offering three forward and three reverse gears. This setup enables the loader to maintain high transmission efficiency, whether it’s moving forward or backward, making it incredibly versatile in various underground tasks.

One of the standout features of this transmission system is its ability to deliver high torque at low speeds. This is particularly beneficial in underground mining, where heavy loads need to be moved efficiently through confined spaces. The specialized closed multi-disc wet brake drive axle used in the loader ensures that the machine can operate effectively even under the most demanding conditions, providing the necessary power and control to get the job done.

3. Simplified Operation with Pilot Control System

Operating heavy machinery in the confines of an underground mine can be challenging, but the CNR LHD loader makes it easier with its pilot control system. This system simplifies the operation of the loader, allowing for more intuitive and responsive control of the machine. The result is increased work efficiency and reduced operator fatigue, which are crucial factors in maintaining productivity and safety in mining operations.

The pilot control system streamlines the operation by allowing the operator to control the loader with greater precision. This not only makes the loader easier to handle but also enhances its ability to perform complex tasks in challenging environments. Whether it’s scooping up material or maneuvering through tight tunnels, the pilot control system ensures that the CNR LHD loader performs with exceptional accuracy and efficiency.

4. Durable Electrical System for Harsh Environments

The electrical system of the CNR LHD loader is specially designed to withstand the damp and humid conditions typical of underground mining. With comprehensive waterproofing and moisture protection, the loader’s electrical components are well-guarded against the elements, ensuring reliable performance in any underground environment.

This level of protection is essential in preventing electrical failures that could lead to costly downtime or even safety hazards. By incorporating these protective features, the CNR LHD loader ensures that its electrical system remains operational even in the most challenging conditions, providing miners with a dependable machine that won’t let them down when they need it most.

5. Reliable Wet Brake System

Safety is paramount in underground mining, and the CNR LHD loader takes this seriously with its advanced wet brake system. This system uses a multi-disc wet brake design, which is housed within the drive axle and lubricated with gear oil. This setup not only protects the brake components from damage but also ensures consistent braking performance, even in wet and muddy conditions.

The parking brake is another critical feature, utilizing a spring-applied, hydraulically released mechanism that guarantees safe and reliable braking. This design ensures that the loader can be securely parked on inclines or in other challenging positions without the risk of brake failure. The wet brake system of the CNR LHD loader provides miners with the confidence they need to operate safely in the hazardous conditions of underground mining.

Conclusion

The CNR LHD loader is a powerhouse of efficiency, durability, and safety, specifically designed to excel in the harsh and demanding conditions of underground mining. Its turbocharged power system, advanced transmission, simplified pilot controls, durable electrical components, and reliable wet brake system all work together to create a machine that is as tough as the environment it operates in. For anyone involved in underground mining, the CNR LHD loader is a tool that offers unmatched performance and peace of mind.