Table of Contents

Mining tunnel engineering is a critical aspect of modern mining operations. These tunnels are not just passageways but serve as lifelines that ensure the efficient and safe extraction of valuable resources. With the complexity of geological conditions and the scale of operations, the construction of mining tunnels presents unique challenges. In this blog, we’ll explore five key aspects of mining tunnel engineering that make it a specialized and essential field.

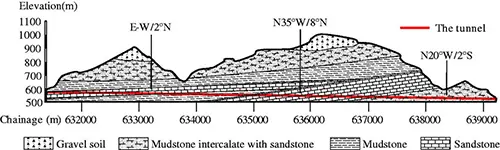

1. Understanding the Complex Geology

One of the most distinctive features of mining tunnel engineering is the complex geological conditions. Unlike ordinary tunnels, mining tunnels must navigate through various layers of rock, some of which may be unstable or prone to collapse. Engineers must conduct thorough geological surveys to understand the terrain and design tunnels that can withstand these conditions. This involves using advanced techniques like seismic surveys, ground-penetrating radar, and drilling to map out the subsurface.

Geological challenges such as underground water, fault lines, and varying rock hardness require customized solutions. For instance, tunnels passing through soft rock may need additional support structures, while those in hard rock might require precision blasting techniques. The goal is to create a stable and safe passage for miners and equipment, which is crucial for the success of any mining operation.

2. Massive Scale and Planning

Mining tunnel engineering projects often cover vast areas, connecting different parts of a mine or facilitating the transport of extracted materials. The scale of these projects can be staggering, requiring meticulous planning and coordination. Engineers must consider factors such as the length of the tunnel, the depth, and the type of materials being transported.

Detailed project management is essential to ensure that the construction stays on schedule and within budget. This includes coordinating various teams, from geologists to construction workers, and ensuring that the necessary resources are available at each stage of the project. The logistics of transporting materials in and out of the tunnel also require careful planning, especially in remote or challenging environments.

3. Specialized Excavation Techniques

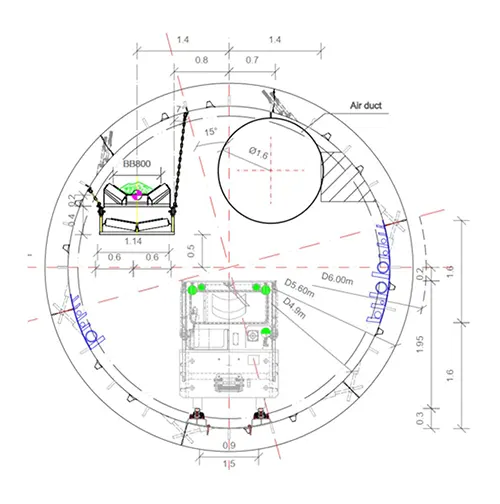

Excavation in mining tunnel engineering is not your average digging operation. Depending on the type of rock and the tunnel’s purpose, different excavation methods may be employed. These include drilling and blasting, tunnel boring machines (TBMs), and even specialized mining equipment designed to handle specific conditions.

In softer ground, engineers might use techniques like ground freezing or the New Austrian Tunneling Method (NATM) to stabilize the tunnel as it is being excavated. In harder rock, precision drilling and controlled blasting are often necessary to break through the rock while minimizing damage to the surrounding area. The choice of excavation method depends on factors such as the type of rock, the tunnel’s size, and the project’s overall timeline.

4. Safety Measures

Safety is a top priority in mining tunnel engineering. The unique hazards associated with underground construction, such as rockfalls, gas leaks, and flooding, require specialized safety protocols. Engineers must design tunnels with safety in mind, incorporating features like ventilation systems, emergency exits, and monitoring equipment.

During construction, continuous monitoring of the tunnel’s stability is crucial. This can involve using sensors to detect shifts in the rock or changes in pressure, which might indicate potential problems. In addition, strict safety training and procedures must be followed by all workers to minimize the risk of accidents. Safety measures also extend to the post-construction phase, where regular inspections and maintenance are required to ensure the tunnel remains safe for use.

5. Future Trends and Innovations

The field of mining tunnel engineering is constantly evolving, with new technologies and methods being developed to improve efficiency and safety. One of the most exciting trends is the use of automation and robotics in tunnel construction. Automated equipment can work faster and more accurately than human operators, reducing the time and cost of construction.

In addition, advances in materials science are leading to the development of stronger and more durable support structures, which can enhance the stability of tunnels in even the most challenging conditions. Environmental sustainability is also becoming a key consideration, with engineers exploring ways to minimize the environmental impact of tunnel construction and operation.

Conclusion

Mining tunnel engineering is a complex and specialized field that plays a critical role in the success of mining operations. From navigating challenging geological conditions to ensuring the safety of workers, engineers must consider a wide range of factors in the design and construction of mining tunnels. As technology continues to advance, the future of mining tunnel engineering looks promising, with new innovations set to make the process faster, safer, and more efficient.

In conclusion, whether you’re a mining professional or just curious about the inner workings of the industry, understanding the key aspects of mining tunnel engineering can provide valuable insights into this essential and fascinating field.