Table of Contents

Introduction

When it comes to heavy-duty earthmoving and construction, nothing beats the sheer power and versatility of the scraper. Imagine a machine that can slice through the earth like a hot knife through butter, scoop up the soil, transport it, and even smooth it out—all in one go! If you’ve never met a scraper before, consider this your first date with a true heavy-duty multitasker.

But before we dive into the nitty-gritty, let’s take a look at what makes this machine a must-have on construction sites worldwide. Spoiler alert: This isn’t just another piece of machinery; it’s a game-changer.

1. The Anatomy of a Scraper: Built to Conquer

Scrapers are engineering marvels. At their core, they are made up of a bucket, cutting blade, soil-breaking knife, rotating and sliding baffles, and a sturdy support structure. The bucket does the heavy lifting—literally—scooping up the soil and transporting it to the desired location. The cutting blade slices through the ground like it’s slicing cake, and the soil-breaking knife ensures that even the toughest chunks of earth don’t stand a chance.

The support structure is like the backbone of the scraper, holding everything together and making sure the machine functions smoothly. Simple yet effective, the design ensures that scrapers can tackle even the toughest jobs.

2. Types of Scrapers: A Machine for Every Job

Scrapers come in various shapes and sizes, each designed for specific tasks and conditions. Here’s a quick rundown:

– Self-Propelled Scrapers: These bad boys are the jocks of the construction world. They consist of a tractor unit and a scraper unit, connected by a hinge. The tractor pulls the scraper, which does the dirty work. These machines are incredibly versatile, boasting a travel distance of over 1500 meters.

– Towed Scrapers: These require a tractor to pull them and are usually equipped with wide, low-pressure tires. They’re perfect for softer soil in hilly areas but have a shorter range (50-500 meters) and are less commonly used in modern engineering.

– Engine Configuration: Scrapers can be powered by either a single engine or dual engines. Dual-engine scrapers are a step up, providing additional power for more demanding tasks.

– Axle Configuration: Two-axle scrapers are the norm, but three-axle models are also available, offering more stability and power.

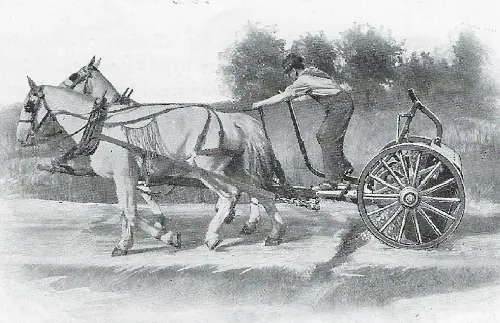

3. A Brief History: From Horsepower to Horsepower

Scrapers have come a long way since their inception. The first scrapers appeared in the 18th century and were literally horse-powered, dragged along the ground by our equine friends. Fast forward to 1883, and the first wheeled, all-metal scraper was born. By 1938, self-propelled scrapers were making waves, and in 1949, the dual-engine scraper took the stage.

China joined the scraper revolution in the 1960s. The first Chinese self-propelled scraper, the C-6106, was a product of collaboration between the Zhengzhou Engineering Machinery Factory and Xiamen Engineering Machinery Factory. By the 1970s, China was rolling out its own advanced models like the CL7, marking a significant leap in technology.

4. How Scrapers Get the Job Done: The Four-Step Process

Scrapers are like the Swiss Army knives of earthmoving, capable of performing multiple tasks with precision. Here’s how they do it:

1. Scraping: The bucket drops, the door opens, and the cutting blade begins slicing through the soil. The soil is collected in the bucket until it’s full.

2. Transporting: With a full load, the scraper moves to the dump site.

3. Unloading: The bucket door opens, and the scraper’s blade levels the soil as it’s dumped.

4. Returning: The scraper returns to its starting point to repeat the process.

5. Choosing the Right Scraper: It’s All About the Job

Selecting the right scraper for the job depends on various factors, including the size of the project, the distance the soil needs to be transported, and the type of soil being worked on. For shorter distances and softer soils, a towed scraper may be sufficient. However, for larger projects and tougher soils, a self-propelled scraper is the way to go.

The method of unloading also varies. Scrapers can use forced unloading, semi-forced unloading, or free unloading. Forced unloading is the most thorough, but it also consumes the most power. On the other hand, free unloading is more energy-efficient but may leave some soil behind.

6. Safety First: Operating a Scraper

Operating a scraper is not for the faint of heart. These machines are powerful, and safety should always be a priority. Here are some tips:

– Pre-Operation Checks: Always inspect the work area and the machine before starting. Check the hydraulic system, lubricate all points, and ensure the tires and brakes are in good condition.

– Driving Safely: Be cautious, especially in narrow areas or when making sharp turns. Use the bucket to help stop the machine if needed.

– Power Down Safely: When finished, park the scraper on a flat surface, lower the bucket, and disconnect the power.

7. The Future of Scrapers: Innovation and Efficiency

The future of scrapers looks bright, with advancements in technology making these machines even more efficient and environmentally friendly. Modern scrapers are equipped with state-of-the-art systems like electronic control systems, hydraulic braking, and automated unloading.

For instance, scrapers now feature advanced engines like the Cummins QSM11, which meet stringent emission standards while providing powerful performance. Hydraulic systems, such as those from Rexroth, ensure stability and reliability, while materials like Hardox steel from Sweden offer unparalleled durability.

Conclusion

Scrapers are the unsung heroes of the construction world. Whether you’re flattening a massive site for a new airport or scooping up debris after a natural disaster, these machines are indispensable. With a history rich in innovation and a future full of promise, scrapers continue to be a cornerstone of earthmoving and construction technology.

So the next time you see one of these multitasking giants on a job site, give it a nod of respect. It’s doing the work of several machines, all rolled into one—efficiently, effectively, and with a touch of finesse.