Table of Contents

Subsurface mining, or underground mining, is an essential method for extracting minerals and metals buried deep beneath the Earth’s surface. Whether it’s gold, silver, coal, or other precious materials, subsurface mining plays a pivotal role in providing the raw materials needed for various industries. But what exactly does subsurface mining entail, and why is it so critical? Let’s delve into the fascinating world of subsurface mining with a friendly and humorous twist, making complex concepts easier to grasp while uncovering the seven essential insights into this deep-digging industry.

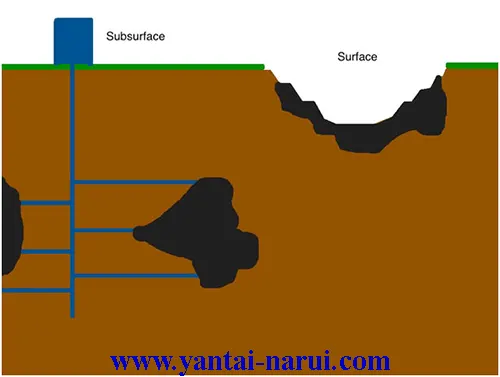

1. What is Subsurface Mining? The Basics

Imagine digging a tunnel in your backyard, except instead of striking a water pipe or your neighbor’s fence, you hit a vein of gold! Well, that’s a simplistic view of subsurface mining. This mining method involves digging tunnels or shafts to access mineral deposits that lie deep beneath the Earth’s surface. While surface mining involves scraping away the Earth’s crust like a burnt toast to get to the jam (minerals), subsurface mining is like diving deep into the Earth’s core to find that elusive jar of jam buried under layers of rock.

Subsurface mining is typically employed when mineral deposits are located too deep for surface mining to be viable. The depth can range from a few hundred meters to over 3 kilometers. For example, the Mponeng Gold Mine in South Africa, the world’s deepest, operates at an incredible depth of 3.1 kilometers.

2. The Different Types of Subsurface Mining

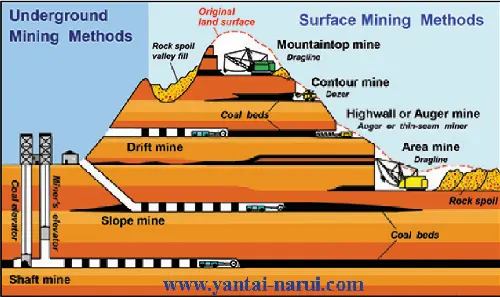

Subsurface mining isn’t just one-size-fits-all. Just as you wouldn’t use a spoon to dig a swimming pool, miners have developed specific methods depending on the type of mineral and the geological conditions. The most common techniques include stoping, caving, and block caving, each with its unique approach:

– Stoping: Picture miners creating horizontal tunnels, almost like hollowing out a chocolate bar from the inside. Stoping is ideal for extracting wide, horizontal deposits known as seams or narrow vertical ones called veins. It leaves behind a network of empty rooms or tunnels, making it a delicate balancing act to ensure the structure doesn’t collapse.

– Block Caving: Think of this as the lazy way to mine (but way more complex). Miners strategically drill and blast large blocks of ore, causing them to collapse under their weight, making the extraction process more efficient. While this method is cost-effective and great for large ore bodies, it requires meticulous planning and monitoring to prevent accidents.

– Room and Pillar Mining: This method involves mining rooms of ore while leaving pillars intact to support the mine’s roof. It’s like removing Jenga blocks carefully without causing the tower to fall. This method is commonly used in coal mining.

– Longwall Mining: A highly automated form of mining where a coal shearer moves along a panel, cutting the ore and allowing the roof to collapse behind it. This method is both efficient and effective, recovering up to 90% of the available coal.

3. The Tech-Savvy Miner: How Technology is Transforming Subsurface Mining

Gone are the days when mining was just pickaxes and canaries. Today, the industry is undergoing a technological revolution, making the process more efficient, safer, and smarter. Automation is a key trend, with miners now controlling operations remotely, reducing the risk of accidents and ensuring precision in ore extraction.

Advanced equipment like remote-controlled drills, GPS mapping, and computer systems are now standard in modern mines. These tools allow miners to identify ore locations with pinpoint accuracy and manage the mining process more effectively. Plus, with automated machinery, the number of workers required to venture deep underground is significantly reduced, leading to fewer safety hazards and better working conditions.

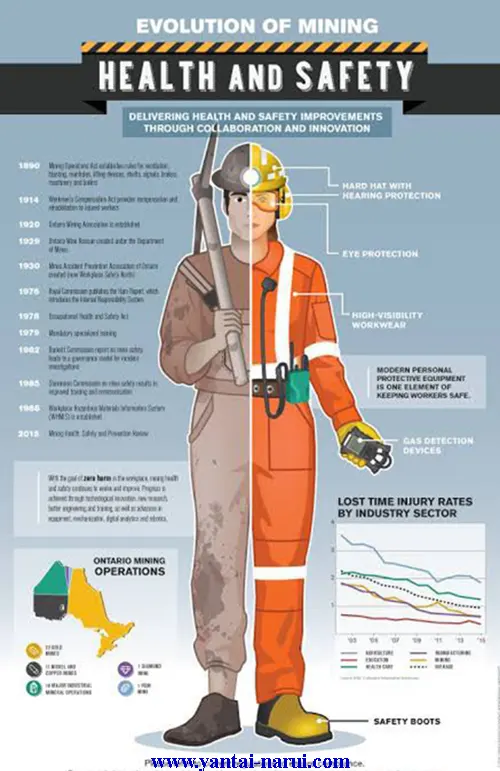

4. Safety First: Navigating the Dangers of Subsurface Mining

Let’s face it, digging deep into the Earth’s crust is no walk in the park. Subsurface mining is inherently dangerous, with risks like cave-ins, flooding, toxic gas exposure, and even seismic activity. However, modern safety measures and technological advancements have significantly reduced these dangers.

Mines today are equipped with extensive ventilation systems, water drainage facilities, and robust communication networks. These systems ensure that miners can breathe clean air, avoid water accumulation, and stay connected with the surface at all times. Additionally, escape routes and emergency plans are in place to evacuate workers swiftly in case of an emergency.

But safety isn’t just about reactive measures; it’s also about proactive planning. Before any mining operation begins, extensive geological surveys are conducted to understand the composition of the rocks, the orientation of the ore deposits, and the potential hazards. This data is then used to design the mine and develop a detailed safety plan.

5. Environmental Impact: Striking a Balance with Mother Nature

Mining, by its nature, disturbs the environment. However, subsurface mining is often considered more environmentally friendly than surface mining because it leaves the landscape above largely intact. But that doesn’t mean it’s without its challenges.

One of the main environmental concerns with subsurface mining is waste management. The ore extraction process generates waste material that must be disposed of carefully to avoid contaminating soil and water sources. Modern mines are increasingly adopting environmentally-friendly techniques such as in-situ leaching, where chemicals dissolve minerals underground, and the solution is then pumped out. This method reduces surface disruption and minimizes waste generation.

Moreover, as environmental regulations become stricter, mining companies are now more focused on reducing their ecological footprint. This includes everything from minimizing land use and energy consumption to restoring mined land to its natural state after operations have ceased.

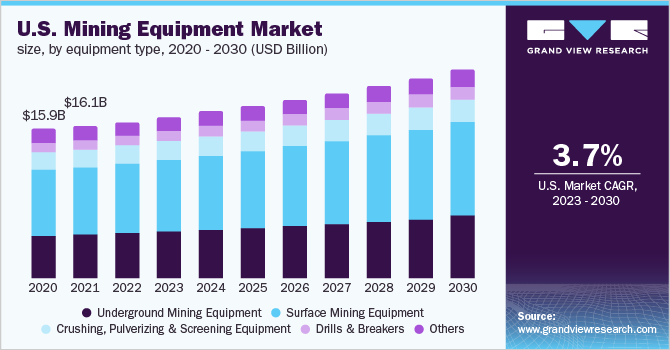

6. The Economics of Going Underground: Costs, Profits, and the Global Market

Subsurface mining is no small investment. The costs involved in digging deep, purchasing advanced equipment, and ensuring safety can be astronomical. But why go through all that trouble? The answer is simple: the rewards often outweigh the risks.

The profitability of subsurface mining largely depends on the value of the minerals being extracted. High-value ores like gold, diamonds, and platinum make the deep dig worthwhile. However, fluctuating market prices can significantly impact the economic viability of a mining project. As mines go deeper, operational costs increase, requiring more sophisticated technology and safety measures, which in turn affects profitability.

On the global stage, subsurface mining plays a crucial role in powering industries and economies. Countries like the United States, Australia, China, Russia, and South Africa are major players in this field, with mining contributing significantly to their GDPs.

7. The Future of Subsurface Mining: What Lies Ahead?

As the demand for minerals continues to grow, so does the need for more efficient and sustainable mining practices. The future of subsurface mining is set to be shaped by technological innovations, stricter environmental regulations, and a focus on sustainability.

Automation and remote-controlled machinery are likely to become even more prevalent, reducing the need for human workers in dangerous environments. Additionally, the industry is expected to explore new frontiers, venturing into previously untapped regions and deeper into the Earth’s crust.

Sustainability will also play a key role, with mining companies adopting practices that minimize environmental impact and ensure the long-term viability of mining operations. This includes everything from reducing energy consumption and waste generation to rehabilitating mined land.

Conclusion: Digging Deeper, Smarter, and Greener

Subsurface mining is a complex and challenging endeavor, but it’s also one of the most critical processes for obtaining the minerals and metals that drive our modern world. By understanding the various techniques, the role of technology, and the importance of safety and environmental stewardship, we can appreciate the immense effort that goes into extracting these valuable resources.

As we look to the future, it’s clear that subsurface mining will continue to evolve, becoming more efficient, safer, and environmentally friendly. So, the next time you use your smartphone, drive your car, or even sip a cup of coffee, remember that deep beneath the Earth’s surface, a miner’s hard work has made it all possible.