Table of Contents

Introduction

Mining isn’t all about big machines chomping at rocks on the surface. When the treasures lie deep beneath the earth, it’s time to dig down—way down—with underground mining. Imagine Indiana Jones in a hard hat, and you’re halfway there! But, before you start dreaming of golden nuggets and ancient artifacts, let’s explore what underground mining is all about, how it’s done, and the safety rules that keep miners out of trouble.

What is Underground Mining?

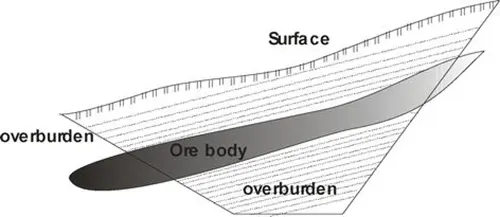

Underground mining is like a hidden treasure hunt, except the treasure is buried deep beneath the earth’s surface. When minerals or ores are located too far below the surface for open-pit mining to be cost-effective, underground mining becomes the method of choice. It’s a process that involves creating tunnels and shafts to reach the ore, and it requires precision, planning, and a dash of bravery.

The Underground Mining Process: Step by Step

Underground mining is no quick grab-and-go operation. It’s a systematic process with several essential steps, each crucial to ensure the efficient and safe extraction of valuable minerals.

1. Orebody Development

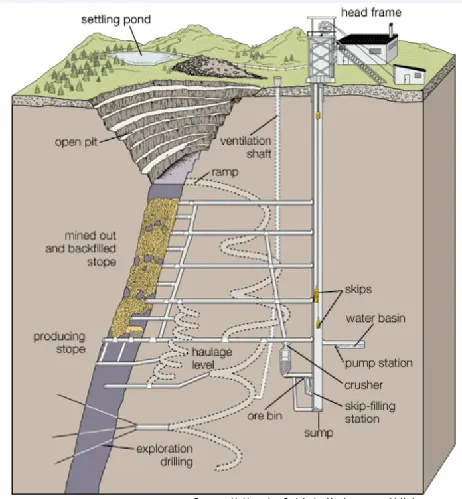

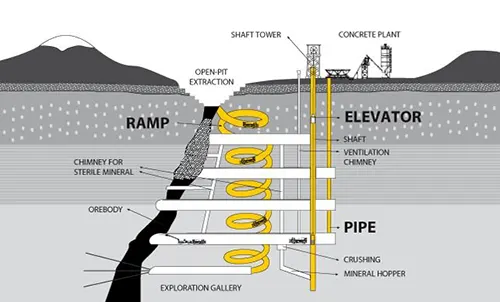

This is the foundation of underground mining—literally! The process begins by developing access to the mineral deposit through shafts, ramps, and tunnels. These passageways are vital for transporting workers, equipment, and, eventually, the mined ore.

– Key Structures: Vertical shafts, inclined shafts, declines, and horizontal drifts.

– Purpose: Access ore bodies and create pathways for future mining operations.

2. Ore Extraction Planning

Planning is everything in mining. This stage involves designing the layout of the mining operation to optimize ore extraction. Decisions are made regarding the sequence in which different parts of the orebody will be mined.

– Considerations: Geological conditions, economic factors, safety protocols.

– Goal: Maximize ore recovery while minimizing costs and risks.

3. Orebody Preparation (Pre-Mining)

Before mining begins, the orebody must be prepared. This involves developing the necessary infrastructure within the mine, such as ventilation systems, transport routes, and support structures.

– Components: Ventilation shafts, haulage roads, and safety supports.

– Outcome: A safe, well-prepared environment ready for mining operations.

4. Mining (Ore Removal)

This is the heart of underground mining—where the ore is actually removed from the earth. Different mining methods are used depending on the orebody’s characteristics, and each method has its unique set of challenges.

– Common Methods: Cut and fill, room and pillar, longwall mining.

– Objective: Safely and efficiently extract the maximum amount of ore.

5. Transportation

Once the ore is extracted, it must be transported to the surface for processing. This involves using specialized machinery to haul the ore up through the shafts and ramps.

– Equipment: Conveyor belts, haul trucks, hoisting systems.

– Challenge: Ensuring efficient and safe transport of large quantities of ore.

6. Crushing and Conveying

The ore doesn’t go straight to the processing plant; it first needs to be broken down into smaller, more manageable pieces. Crushing and conveying systems handle this task underground.

– Purpose: Reduce the size of ore to facilitate easier transport and processing.

– Tools: Crushers, conveyors, and feeders.

7. Ore Processing and Beneficiation

Once on the surface, the ore undergoes processing to extract the valuable minerals. This step often involves crushing, grinding, flotation, and other chemical processes.

– Outcome: Separation of valuable minerals from waste rock.

– Techniques: Gravity separation, flotation, leaching.

8. Waste Management and Disposal

Mining generates a lot of waste, and it’s crucial to manage it properly to minimize environmental impact. This step involves safely disposing of waste materials and reclaiming the land.

– Methods: Backfilling, tailings disposal, land reclamation.

– Goal: Minimize environmental footprint and restore land post-mining.

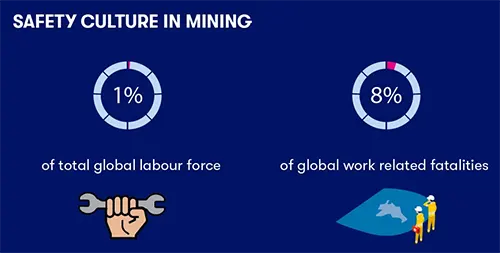

9. Safety Protocols

Safety is paramount in underground mining. The environment is inherently hazardous, with risks such as cave-ins, gas leaks, and equipment malfunctions. Comprehensive safety protocols are essential to protect workers.

– Key Safety Measures: Regular inspections, safety drills, and emergency response plans.

– Objective: Ensure the safety and well-being of all personnel.

10. Monitoring and Evaluation

The mining process doesn’t end once the ore is extracted. Continuous monitoring and evaluation are necessary to ensure the operation remains safe, efficient, and environmentally responsible.

– Tools: Ground-penetrating radar, environmental monitoring systems.

– Purpose: Maintain operational integrity and compliance with regulations.

Common Methods of Underground Mining

Underground mining isn’t a one-size-fits-all affair. The method used depends on several factors, including the orebody’s shape, the rock’s stability, and economic considerations. Here are some of the most common methods:

1. Cut and Fill Mining

This method is like digging a series of steps. Ore is mined in horizontal slices, and once a slice is removed, the void is filled with waste rock or other materials. This process continues slice by slice, ensuring that the mine remains stable.

– Advantages: Flexibility and stability.

– Best For: Steeply dipping ore bodies.

2. Room and Pillar Mining

Think of this method as mining through a checkerboard. Large rooms of ore are mined, leaving pillars of rock to support the roof. These pillars may later be mined in a process known as “retreat mining.”

– Advantages: Simplicity and efficiency.

– Best For: Horizontal or flat ore bodies.

3. Longwall Mining

This is the big leagues of underground mining, primarily used for coal extraction. A long wall of ore is mined in a single slice, and as the wall advances, the roof behind it is allowed to collapse in a controlled manner.

– Advantages: High production rates.

– Best For: Large, continuous ore bodies.

Safety First: Essential Safety Rules in Underground Mining

Safety in underground mining is non-negotiable. Here are some of the fundamental safety measures that every underground mine must follow:

1. Regular Ventilation Checks: Ensure that fresh air circulates throughout the mine to prevent the build-up of toxic gases.

2. Rigorous Inspections: Daily checks of equipment, tunnels, and support structures are essential to catch any potential issues early.

3. Emergency Drills: Regular emergency response drills prepare miners for incidents like cave-ins, gas leaks, or fires.

4. Personal Protective Equipment (PPE): Helmets, respirators, and high-visibility clothing are standard issue for all miners.

5. Communication Systems: Reliable communication systems are crucial to keep all workers informed and coordinated.

Choosing the Right Mining Method

Selecting the right mining method is crucial to ensure safety, efficiency, and profitability. The decision hinges on several factors:

– Geological Conditions: The shape, size, and orientation of the orebody.

– Economic Factors: The cost of extraction versus the value of the ore.

– Safety Considerations: The stability of the surrounding rock and the risks involved.

Conclusion

Underground mining is a complex, challenging, and highly rewarding endeavor. From the initial development of access tunnels to the final ore extraction, every step requires careful planning, execution, and a strong commitment to safety. Whether you’re a mining professional or just someone curious about how those shiny metals end up in your gadgets, understanding the ins and outs of underground mining gives you a newfound appreciation for the industry that powers so much of our modern world.

And remember, the next time you hold a metal object, it probably started its journey deep underground—just like an epic adventure!